The Importance of Rapid Prototyping in the Product Development Lifecycle

In today’s fast-paced hardware industry, speed, accuracy, and innovation are crucial for staying competitive. Engineers and designers need tools that allow them to test ideas quickly, iterate designs, and validate functionality before committing to mass production. Hardware rapid prototyping has become a cornerstone of modern product development, enabling teams to transform concepts into tangible products efficiently while minimizing risk. By creating early prototypes, teams can identify design flaws, refine mechanical and electronic components, optimize user experience, and validate performance well before the final product reaches the market. This approach reduces costs, accelerates development cycles and increases product quality, making it indispensable for electronics, IoT devices, consumer hardware, and industrial equipment.

What is Rapid Prototyping?

Rapid prototyping refers to the process of quickly producing preliminary versions of a product to test form, fit, function, and feasibility. Unlike traditional prototyping, which can be slow and expensive, modern methods allow functional prototypes to be built in days or weeks instead of months. This adaptive approach is a key element of both rapid prototyping for electronics and rapid prototyping in hardware development.

Common prototyping techniques:

- 3D Printing: Quickly creates mechanical components and enclosures with complex geometries.

- CNC Machining: Produces precise, functional prototypes for mechanical and structural testing.

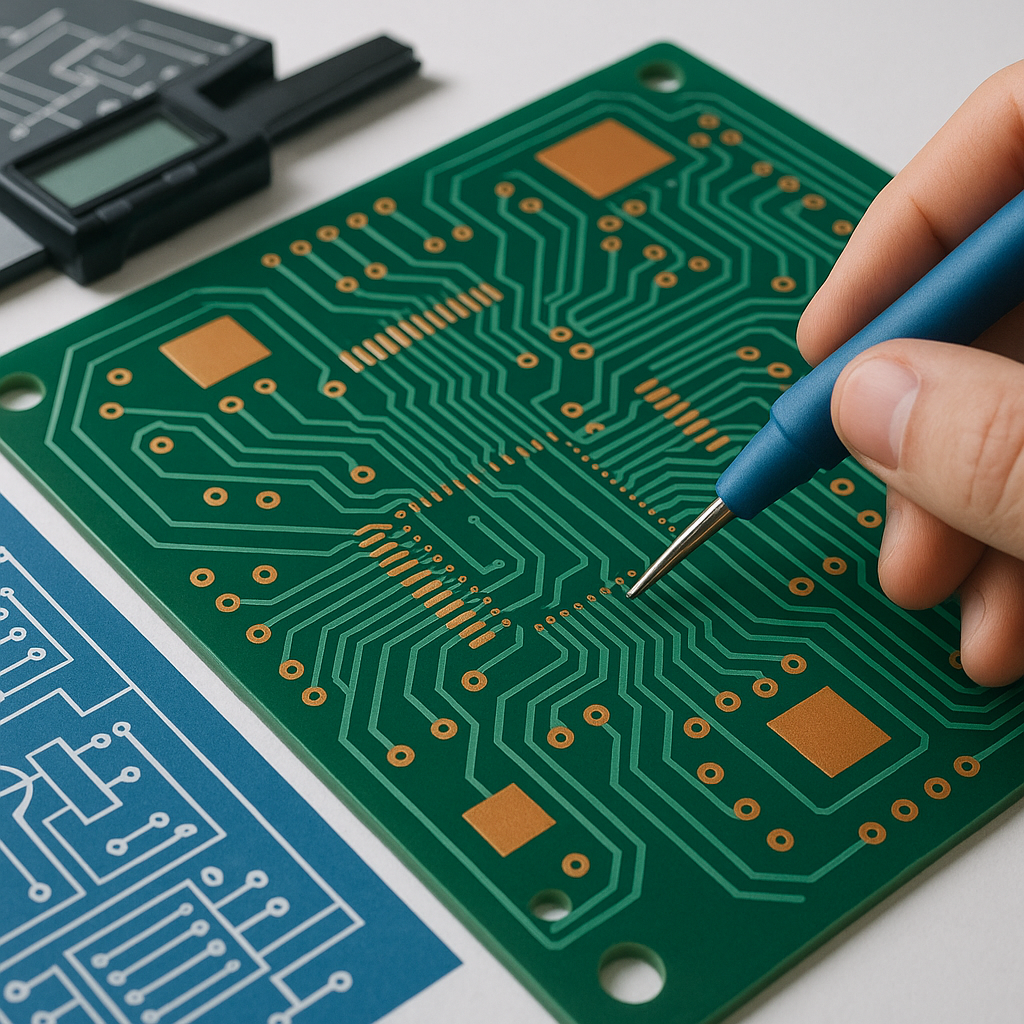

- PCB Fabrication: Enables rapid iteration of electronic circuits to catch design errors early.

- Laser Cutting: Produces accurate shapes for housings, mounts, or structural components.

- Injection Molding & Castings: Creates durable, realistic prototypes for functional and aesthetic evaluation.

- Virtual Simulation: Software testing of electrical, mechanical, and thermal properties before building physical prototypes.

The main goal is to accelerate hardware prototype development, allowing teams to iterate designs, validate concepts, and improve performance efficiently. For instance, during the development of a levitating 360° camera called Moon, our team used hardware rapid prototyping extensively to tackle one of the most challenging hardware concepts imaginable.

Key Benefits of Rapid Prototyping

- Faster Design Validation: Rapid prototypes allow teams to test designs early and often, validating both electronics and mechanical systems. Early 3D-printed enclosures and PCB prototypes help determine optimal internal layout, component placement, and system performance. Testing prototypes at this stage can reveal issues such as vibration, overheating, structural instability, or signal interference problems that could otherwise go unnoticed until final production.

- Cost Efficiency By identifying design flaws early, rapid prototyping reduces expensive rework. Producing a prototype is far cheaper than creating tooling or mass production molds. For the Moon project, we iterated on several levitation system concepts using modular boards and magnetic bases, allowing us to refine the design without wasting costly components or extending the development schedule.

- Improved Collaboration Prototypes serve as a tangible reference for engineers, designers, and stakeholders, making mechanical, electronic, and user interface considerations easier to communicate.

- Encourages Innovation Rapid prototyping promotes experimentation by reducing the cost of failure, enabling teams to explore different materials, sensors, and design configurations.

- Real-World Feedback Integration Prototypes can be tested by end-users, focus groups, or in real field conditions, providing valuable feedback to refine the design before launch. Real-world testing often reveals issues such as vibrational sensitivity, environmental interference, or user-interaction challenges that simulations alone may not fully capture. This feedback enables targeted improvements in sensor calibration, control algorithms, mechanical structure, and overall system performance.

Integrating Rapid Prototyping into the Hardware Development Lifecycle

Rapid prototyping supports and enhances every stage of the hardware development process:

- Concept Development: Ideas are transformed into early prototypes to test feasibility and basic functionality.

- Design Iteration: Prototypes are continuously refined using testing data, helping teams identify issues in thermal management, structural stability, electronics layout, and overall system performance.

- Validation and Testing: Functional, performance, and stress testing ensure that prototypes meet design requirements, including durability, responsiveness, and system behavior.

- Pre-Production: Designs are optimized for manufacturability, ensuring that the final product can be produced efficiently and consistently.

Real-World Applications

- Consumer Electronics: Smartphones, wearables, and smart home devices often rely on rapid prototyping to validate ergonomics, electronics integration, and usability.

- Automotive Hardware: Dashboard components, sensors, and mechanical parts are tested before production.

- IoT Devices: Compact designs benefit from iterative prototyping for circuits, enclosures, and connectivity.

- Industrial Equipment: Prototyping helps verify that components meet operational requirements and durability standards before entering manufacturing.

- Advanced R&D Concepts: Highly ambitious devices can be tested and validated through rapid prototyping methods, enabling innovation previously considered impractical.

Challenges and Considerations

While rapid prototyping provides significant advantages, teams should be aware of several common limitations:

- Material Limitations: Prototyping materials may not fully match the properties or performance or final production materials.

- Accuracy and Precision: Some prototyping methods have tolerances that differ from production-grade manufacturing, which may affect fit or function.

- Cost for Complex Systems: Multi-component or highly detailed prototypes can still be expensive to produce, especially in early stages.

- Partial Functional Testing: Early prototypes may not fully capture integrated system performance, requiring additional testing in later phases.

Even with these considerations, the advantages clearly outweigh the drawbacks, especially when it comes to reducing risk, accelerating learning, and fostering innovation..

Best Practices

- Focus on high-risk or critical components first

- Iterate rapidly using short feedback loops.

- Employ modular designs to enable quick swapping and testing of alternatives.

- Combine physical and virtual prototypes for comprehensive evaluation.

- Engage cross-functional teams early to enhance collaboration.

- Plan for manufacturability from the beginning.

- Document every iteration and test result for traceability and insight.

Conclusion

Hardware rapid prototyping is a strategic necessity, not an optional step. Integrating it into the product development lifecycle allows teams to accelerate time-to-market, reduce costs, minimize errors, and improve product quality.

Companies that embrace this approach gain a competitive edge, delivering innovative, reliable, and well-tested hardware products to a rapidly evolving global market. Leveraging rapid prototyping methods and hardware prototype development ensures faster validation, optimized designs, and reduced risk before production.